H2Bidea Research and Development Goals

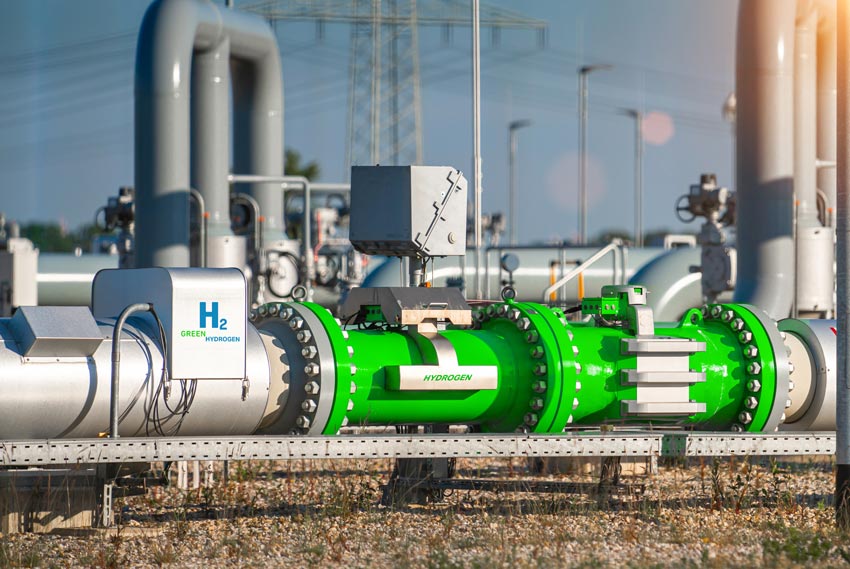

The H2Bidea projects seeks to develop technological solutions to roll out new ‘100% hydrogen distribution networks’ to drive green hydrogen valleys and industrial decarbonisation. The following goals will be addressed:

Commercial and strategic goals

Technical goals

The H2BIDEA project meets the main challenge of industrial decarbonisation by rolling out new ‘100% hydrogen distribution networks’ to create green hydrogen valleys. Specific challenges have been defined in the framework of the project that are explained below:

| STATE OF THE ART | NEW KNOWLEDGE AND NEW TECHNOLOGICAL DEVELOPMENTS (H2BIDEA) |

|---|---|

Tools to design and manage the 100% H2 network• Tools for modelling consumption and demand of the NG network. No tools are known for the 100% H2 network. |

Advanced tool to optimise the design and operating of the hydrogen gas distribution network including matching supply and demand. This tool will envisage the injection, transporting, compression, storage and consumption of H2 gas. This tool will enable optimised 100% H2 distribution networks to be designed, while always guaranteeing security of supply. The tool will allow Hydrogen Valleys to be modelled and tested, using the electrolyser production curves and H2 demand curves of the customer, with different storage system configurations to cover the transition periods, in order to determine the sizes, technologies and optimum locations to guarantee security of supply. |

Structural Integrity• GN+‹20%H2 distribution network: Knowledge of the performance of materials, components and equipment that form part of the NG network and up to 20% H2. Sufficient knowledge is not available on 100% hydrogen, particularly regarding safety margins and defect sizes that the infrastructure can tolerate, or the level of conservatism (safety margins) provided by the design standards using safety factors. |

• Better knowledge of the hydrogen embrittlement and crackling phenomenon and its relationship with the mechanical properties and microstructure of the network’s materials and components. |

100% H2 pipelines• Better understanding is needed of the mechanisms and mitigating the effects of hydrogen embrittlement (HE) in steels for pipelines for pure hydrogen distribution, for a safe infrastructure and to avoid unexpected failures under lower than design loads. |

• Better knowledge of the hydrogen embrittlement and crackling phenomenon and its relationship with the mechanical properties and microstructure. |

100% H2 Compressor• Conventional compressors. |

• Oil-free compressor |

100% H2 Boiler• Boiler conversion kit up to 20% H2. |

• New conversion kit for a boiler with a BeeEngine combustion system to 100% H2. |

H2 Transmitter• Catalytic sensor with significant limitations, such as catalytic poisoning with substances able to inhibit detection and even deteriorate the sensor (Type I). |

• New developments capable of exceeding the limits of current prevailing technology (catalytic). |

Advanced methodologies for the transition to the use of H2 in industrial decarbonisation• There is some research and real-world application examples for certain sectors, but more development and testing are still needed to move towards more widespread and effective application. |

The developments will be validated through a case study on the regional energy system of the Basque Country (CALCINOR), with special emphasis on the decarbonisation of the industrial sector and the role of H2. |

100% H2 distribution network• Blending distribution and transport networks (natural gas with <20% H2). Distribution network design• Lack of information on configurations to optimise their safe running and operating. |

• H2BIDEA Solution: 100% hydrogen gas distribution network, including key aspects such as transporting, compression and localised storage, measurement, configurations and safety and operability. |

Regulatory frameworks and procedures of the 100% H2 distribution network• There are no rules or regulations that determine the configuration of customer facilities and how to measure their consumption. |

• Research and test the different operating procedures of 100% H2 distribution networks in order to work in safety (H2TestLab). |